Case study iSpray – External lubrication system

Case study iSpray – External lubrication system

The Challenge Punch sticking, hardness stability, and high ejection…

Exhibition | Achema - Frankfurt, Germany - June 10-14, 2024

Exhibition | Achema - Frankfurt, Germany - June 10-14, 2024

Embark on a journey of innovation with us at…

New partner for Q-Control Division

New partner for Q-Control Division

We are delighted to enter into a new collaboration…

Industry 4.0: the key benefits of Pharma Technology's software and new OPC UA communication

Industry 4.0: the key benefits of Pharma Technology's software and new OPC UA communication

For more than 28 years now, Pharma Technology has…

What is the cornerstone of flawless IPC testing?

What is the cornerstone of flawless IPC testing?

Advantages of In-process Quality Control Testing Atline In-process tablet…

Digital equipment 's showcase

Digital equipment 's showcase

As we unfortunately cannot participate in events & exhibitions…

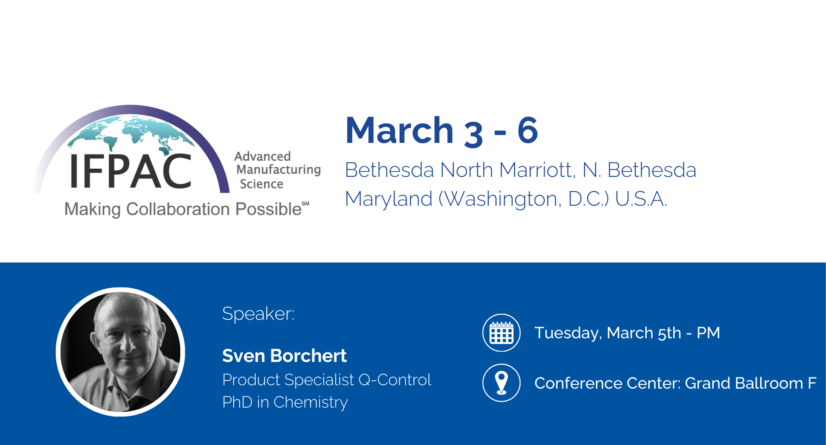

We will be present at IFPAC next month, the essential meeting place for the latest developments in Process Analytical Technology (PAT), Quality by Design (QbD), and overall process monitoring & control within the Pharmaceutical.

We are looking forward to sharing in discussions about the current challenges, as well as the future needs of the industry.

Don’t miss the opportunity to meet our expert Sven Borchert, Product Specialist for the Quality Control Division, who will present our latest developments in PAT during his talk “100% Inspection of Tablet Mass, Thickness, API Content, Porosity, and Hardness“.

In an era where precision and reliability define pharmaceutical excellence, understanding the intricacies of tablet production is more crucial than ever. This talk will delve into the latest technologies and methodologies in 100% inspection, ensuring each tablet meets the highest standards of quality and efficacy. From groundbreaking technologies to measure mass and thickness, to advanced strategies for assessing API content, porosity, and hardness, we’ll cover the spectrum of challenges and solutions in tablet manufacturing.

SAVE THE DATE

ABSTRACT

If no PAT is used for conventional batch or continuous manufacturing, the quality of the manufactured medicines needs to be assessed based on adequate sampling and existing release standards and methods. These are tests with ‘Pass’ or ‘Fail’ statements, that apply for the entire batch, based on a limited number of adequately sampled specimen.

As these tests happen at the end of the manufacturing process the question comes up, how to manage the

production to be ensure these tests pass?

Many initiatives have been published since 2000 to implement new statistical methodologies ensuring that a batch could meet the release tests.

Focus on on-line and in-line methods for the in-process control of manufactured tablets has increased, with view to secure batch releases and ultimately to enable real time release testing.

Tablet porosity and tablet breaking force (or tablet hardness) are known to impact disintegration and dissolution behaviors. Being able to monitor these tablet properties to ensure passed dissolution tests was the driver of this case study.