Tablet and Capsule Visual Inspection

Tablet and Capsule Visual Inspection

The T/CVIS-NSR Viswill inspection machines automatically inspect 360° of…

EXHIBITION | PCI Days - Warsaw, Poland - 8-9 September 2021

EXHIBITION | PCI Days - Warsaw, Poland - 8-9 September 2021

Meet us at PCI Days in Poland (September 8th &…

Exhibition | Asia Pharma Expo - Feb 29 to March 2, 2024

Exhibition | Asia Pharma Expo - Feb 29 to March 2, 2024

Come visit us during the Asia Pharma Expo in…

Success Story | Achieve extra polishing with food supplements

Success Story | Achieve extra polishing with food supplements

“Our challenge is to get a clean, shiny capsule,…

Demanding superior sorting capabilities for your packaging line

Demanding superior sorting capabilities for your packaging line

The implementation of a tablet sorting device upstream of…

ATEX Certification

ATEX Certification

Pharma Technology just got certification following the ATEX Directive…

June 13, 2022

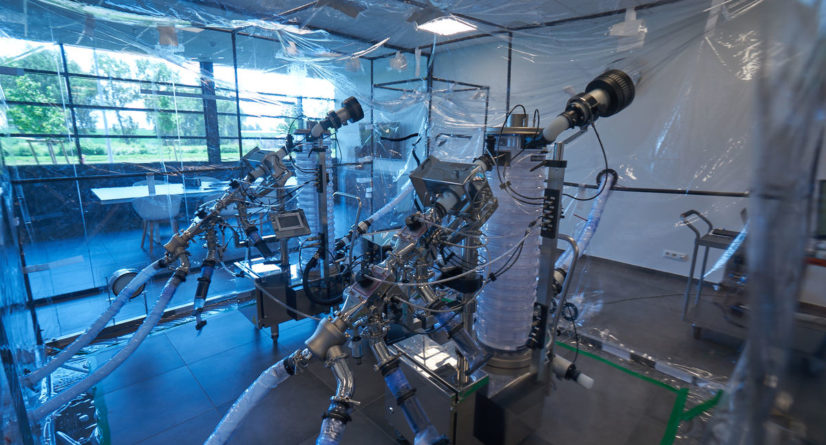

This study was conducted to assess the containment performance of two Pharma Technology Dedusters and Metal Checks, iFlex 750 CE SG D2 HC ,which will be installed in a High Containment Operation facility. The study was conducted on May 11 and 12, 2022 with the assistance of [customer name] and Samih Marhoum, Project Engineer at Pharma Technology. The containment performance target for this equipment was 1.0 µg/m3.

Methods

During the test, data was collected via area air samples, surface samples, and real-time dust monitoring. This information was collected before, during, and after simulated tablet dedusting activities. Six process simulations were completed for each piece of equipment, as part of this study. The surrogate used was prepared by [the customer] in a location separate from the testing enclosure. The test protocol was written by [the customer] following the general sampling guidelines in the ISPE Good Practice Guide–Assessing the Particulate Containment Performance of Pharmaceutical Equipment. Two background (n = 2) and forty-four area (n = 44) air samples were collected during the study. In addition, twenty (n=20) surface samples were collected.

All background and area air samples were collected with MSA Escort Elf™ battery operated pumps calibrated to a known flow rate of 2.2 liters per minute (LPM). Air was drawn through 1.0 micrometer (µm) pore-sized 25 mm PTFE filters. These filters were pre-verified by Bureau Veritas Laboratories to be free from [HAPI product] contamination and mounted in a 2-piece conductive cassette (SKC 225-1725). All air sampling pumps used for the study were calibrated before and after each use with a Bios Defender air flow calibrator per customary industrial hygiene practice. The Bios Defender air flow calibrator is considered a primary air flow standard, which is traceable to a National Institute of Standards and Technology (NIST) standard. A field blank sample was included for each cycle. The field blanks were collected as a check of field handling and shipping procedures, and to ensure that the sampling media was not contaminated before or after sampling.

Surface samples were collected at strategic locations throughout the testing enclosure using Texwipes (TX-714). All surface samples were collected over a 100 cm2 surface area. Surface samples were collected by traversing the area, then flipping the swab over, rotating it 90 degrees, and traversing the area again perpendicular to the first traverse. Two field blanks were collected and sent for analysis. These samples were collected as a check of field handling and shipping procedures, and to ensure that the media was not contaminated before or after sampling.

Direct reading measurements were taken at points around the equipment using an optical aerosol meter (Thermo Scientific pDR-1500). These measurements were used to determine if leakage occurred during the test.

Analysis

Analysis of all samples was conducted by a fully accredited laboratory to perform analyses of pharmaceutical industrial hygiene samples by the Committee on Laboratory Accreditation of the American Industrial Hygiene Association (AIHA) and participates successfully in the Pharmaceutical Proficiency Analytical Testing (PAT) Program administered through AIHA. The PAT program is designed to assure adequate quality assurance / quality control (QA/QC) by participating laboratories.

Both the air and surface samples were analyzed by ion chromatography (IC) in accordance with the analytical procedures contained in the validated method LZ SOP-00408. The laboratory limit of detection (LOD) for the air samples is reported as 0.001 micrograms per sample (µg/sample) while the LOD for the surface samples is 0.05 micrograms per sample (µg/sample).

Description of Environmental Conditions

The environmental conditions within the testing enclosure was consistent throughout the two-day study. The equipment and testing enclosure were deemed to be structurally sound prior to the start of the study. No visible dust was observed on surfaces throughout the enclosure prior to initiating the test. All environmental conditions were deemed acceptable according to the SMEPAC protocol and ISPE guidelines prior to the test.

Description of the Equipment and Process Tested

Five process simulations were completed on machine one. Six process simulations were completed on machine two. On each machine, the first five process simulations represented typical production activities. The last cycle replicated the cleaning process. This cycle was omitted on machine number one due to time constraints associated with the project.

Each production simulations involved charging 30,000 placebo tablets spiked with [HAPI product] into the deduster. The quantity of [HAPI product] added to each sub-lot was approximately 5% (± 3%). Tablets were fed into the deduster from a continuous liner bag attached to a charge hose wrapped in continuous liner. Tablets were dedusted and discharged through a continuous liner wrapped discharge hose into two continuous liner bags. During the production simulations, tablet samples were triggered at the control panel. Midway through each production simulation, the manual diverter was used to divert tablets to the other continuous liner discharge bag.

The WIP skid was connected to machine two before the test began. This allowed for seamless initiation of the cleaning simulation once the production simulations were complete. The cleaning simulation was automated and required no operator intervention. During this cycle, a pinhole water leak was observed near the vacuum line.

Upon completing each process simulation, the process was stopped, and all air samples were collected for an additional 15 minutes per ISPE guidelines.

Results

The sampling results presented in this report reflect site conditions as they existed at the time of the study as well as observations made by [the customer] personnel. The containment performance target for this SMEPAC was 1.0 µg/m3. In addition to the active air samples collected during this SMEPAC study real-time dust data was collected using a pDR-1500. During the test, real-time dust concentrations ranged for 0.1 to 1.5 µg/m3 at various points around the dedusters.

Conclusions

The sample results ranged from <0.00869 to 0.141 µg/m3, with an average concentration of 0.0239 µg/m3. In addition, the surface sample results demonstrated minimal change between pre- and post-simulation activities. Based on these results, both Pharma Technology Dedusters and Metal checks have passed the SMEPAC.