Roadshow | Book your stop for June in Poland

Roadshow | Book your stop for June in Poland

Our demonstration truck is ready to head out on…

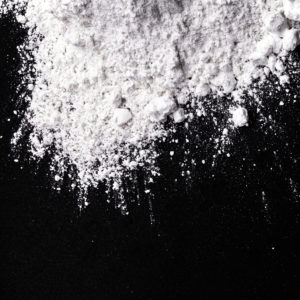

Addressing Dust Accumulation in Tablet Manufacturing

Addressing Dust Accumulation in Tablet Manufacturing

Dedusting equipment and techniques address problems associated with tablet…

Pharma Technology nominated as Trends Gazelle 2023

Pharma Technology nominated as Trends Gazelle 2023

Pharma Technology has been once again nominated as Trends…

PT Inc. doubles up its North American process equipment demonstration capacity !

PT Inc. doubles up its North American process equipment demonstration capacity !

PT Inc., the oral solid dose process equipment specialist…

Tablet and Capsule Visual Inspection

Tablet and Capsule Visual Inspection

The T/CVIS-NSR Viswill inspection machines automatically inspect 360° of…

Exhibition | IFPAC - Cortona, Italy - October 8-11, 2023

Exhibition | IFPAC - Cortona, Italy - October 8-11, 2023

We will take part in the IFPAC Cortona Conference…

After 3 weeks trials with an iCaps capsule polisher, a Swiss company conclude that the machine fits they requirements for an OEB5 product.

The main decision factors were:

High Containment Pharma production requires reliable equipment to guarantee efficiency, product containment, process repeatability, and smooth handling.

Before sending the equipment to customer site, it is usually fully inspected and tested by the customer during a Factory Acceptance Test. This FAT being performed at manufacturer site.

However, the current travel measures put in place in the context of Covid-19 no longer allow the carrying out of this test… Or at least, not in that form!

The Solution

Thanks to today’s communication technology, an online FAT protocol has been created between customer and Pharma Technology.

This protocol ensures that all aspects of a standard FAT are verified as in a “face to face” meeting. All needed documents were submitted prior to the online FAT for engineer’s reviews and comments

On the day of the FAT inspection process, the iCaps “HC” High Containment unit was installed in a professional FAT numeric studio to conduct the test with the representatives. Throughout this process, documents were shared and inspected, while remotes high-quality camera were transmitting the tests live.

The following people were participating on the customer site:

The Results

As everything was well prepared and professionally organized from both sides, the FAT took 1 ½ days and reached a very efficient level in terms of quality and time.

In front of the High-Quality camera lens, engineer achieved the following inspections:

In Summary

Pharma Technology Customer Service completed a great and very efficient work thanks to a very proactive attitude, an attentive response, and a very professional online FAT service offer.

FAT passed successfully and the iCaps “HC” machine has been delivered. Customer can now finalize line installation and validation in a safe way.

THANK YOU to this Swiss customer for his testimony ! “HC” High Containment ≤OEB5 – iCaps capsule polisher with metal check | Pharmatec