In-house repair service

In-house repair service

We react to this lockdown period changing the way…

Tablet and Capsule Visual Inspection

Tablet and Capsule Visual Inspection

The T/CVIS-NSR Viswill inspection machines automatically inspect 360° of…

Success Story | Achieve extra polishing with food supplements

Success Story | Achieve extra polishing with food supplements

“Our challenge is to get a clean, shiny capsule,…

New agent in Romania to represent Pharma Technology

New agent in Romania to represent Pharma Technology

We are pleased to announce our new collaboration with…

Pharma Technology thinks green

Pharma Technology thinks green

Pharma Technology headquarter is located in Nivelles in a…

eFlex vs. iSeries

eFlex vs. iSeries

The Challenge Today we often hear about intelligent machines,…

Introduction

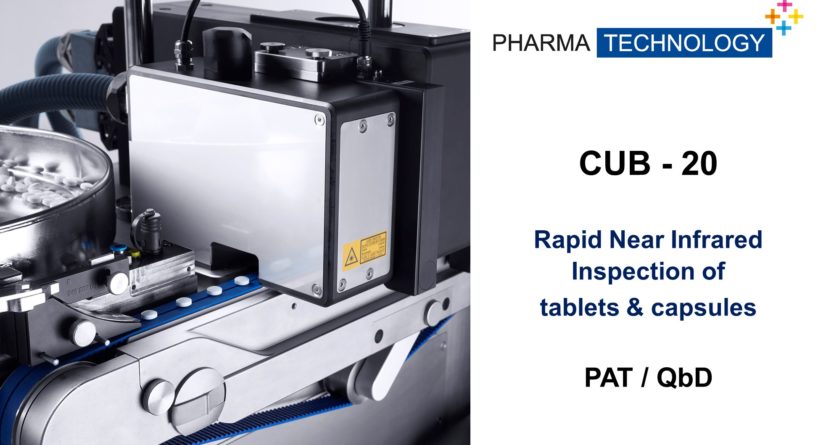

The new CUB-20 inspection machine from Pharma Technology was launched in April 2021 and provides comprehensive, non-destructive prediction of the API fraction in tablets or capsules. Combining innovative Laser Scanner with NIR multipoint technology and modern design with user-friendly GMP compliant software, the CUB-20 is the dedicated bench top machine for the pharmaceutical industry.

Format changes are simple, fast, and supported by HMI guidance. An OPC UA communication protocol ensures rapid and safe data handling. Each individual tablet can be measured up to a speed of 20.000 tablets per hour and the resulting API fraction values decide if the product is accepted or rejected. Thus, the CUB-20 can act as a final quality tool preventing all non-compliant products from reaching the market or as a Quality by Design (QbD) approach using API fraction values to monitor upstream process steps.

Application Fields

The CUB-20 can be used in multiples applications as an off-line, at-line or on-line tool. Typical off-line applications are the use in Research and Development: process development and as a PAT toolbox, process stability studies, clinical batch testing, prove of global batch quality for CMO and the detection of counterfeit products. Finding the optimal measuring parameters in terms of integration time and distance between the probe and the tablet is guided by the software and automatically set in the recipe. Further, integrated DOE in the software supports the user in rapid and faultless spectra acquisition for chemometrics. After finalizing the NIR model, it can be easily transferred to the CU-120 in line inspection machine in the process.

For at-line applications the CUB-20 allows stratified sampling improving Real Time Decision, helps validating new manufacturing processes, especially continuous manufacturing, and can serve multiple lines. Lastly in the on-line mode the CUB-20 supplies automated sampling at regular intervals and can be used as a downstream batch saver function. Therefore, subsequently, the batch can be supplied to the machine, the tablets are measured, and all non-conforming products are rejected. The release quality checks can be repeated with the remaining product and the batch can be released.

An external 4-Paramter tester on the side can measure the mass, thickness, diameter/length and hardness on a sampling basis.

Inspection Technology of the CUB-20

The core technology of the CUB-20 is a combination of 2D-Laser Scanner and Near Infrared Spatial Resolved Spectroscopy (SRS). Our advanced probe design contains an illumination fiber bundle and nine collimation fibers. These collimation fibers are connected to the 2-dimensional detector of a Hyperspectral Imaging camera with a wavelength range of 950 – 1650 nm. The Hyperspectral Imaging camera is used as a NIR multipoint tool ensuring almost the entire surface of the tablet is scanned during the measurement. Thus, every image result in nine individual NIR spectra. After spectra acquisition, the mean spectrum is calculated, and the API fraction is predicted vs. the calculated NIR model.

A detailed View on the Process of the CUB-20

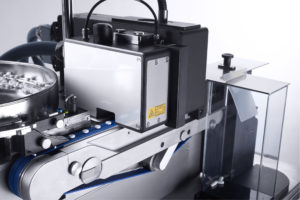

The products are fed as bulk material into the receiving hopper, where they reach the vibrating bowl as they exit the hopper. It is also possible to feed products individually and manually directly on the bowl outlet track.

Each product exits the vibrating bowl one by one, aligned on a slope and continues its way guided, on a vacuumed conveyor. An air curtain removes any exceed of dust from the product to prevent sensor fouling.

During conveying, the products are first checked by the Laser Scanner measuring their length and thickness and locate them along the conveyor. Broken tablets and out of specification tablets are removed before entering the NIR station and confirmed by a counting sensor. The tablet data and are taken to calculate the exact trigger for start/stop of the measurement, the number of NIR images onto the tablets and the corresponding speed of the belt. Then, the products are consecutively checked for their API’s fraction by NIR-SRS.

In production mode, NIR predictions (trends and statistics) are displayed on the central HMI. The batch reports contain the batch inspection statistics and the histograms of the inspected population. “Good” products go straight to the product container, while a high-speed pneumatic valve diverts “out of tolerances & out of plausibility” products to a rejection bin. Rejects are confirmed with a counting sensor.

Conclusion

With the felicitous CUB-20, Pharma Technology offers a solution for the research and development segment, as well as for the continuous manufacturing (CM) process segment for pharmaceutical processes and closing the gap between off-line, at-line and on-line applications.

The main features of the CUB-20 are: its multi-purpose applicability such as off-line, at-line and on-line measurements for research and development applications, the larger sampling compared to existing testers on the market and the step by step guided spectra acquisition for modelling.

Discover the product page: https://pharmatec.be/category/process_development/