CUB-20 Rapid Near Infrared Inspection of tablets & capsules

CUB-20 Rapid Near Infrared Inspection of tablets & capsules

Introduction The new CUB-20 inspection machine from Pharma Technology…

Roadshow | Book your stop for June in Poland

Roadshow | Book your stop for June in Poland

Our demonstration truck is ready to head out on…

The role of Quality Control in the Pharmaceutical Industry

The role of Quality Control in the Pharmaceutical Industry

The pharmaceutical solid dose manufacturing process is increasingly fast-moving…

Exhibition | COPHEX South Korea – APR 22 to APR 25, 2025

Exhibition | COPHEX South Korea – APR 22 to APR 25, 2025

Join us at COPHEX in South Korea – April…

Why Is Automated High-Speed CQA Testing Critical for Modern Pharmaceuticals?

Why Is Automated High-Speed CQA Testing Critical for Modern Pharmaceuticals?

Today’s modern pharmaceutical OSD industry puts increasingly higher demands…

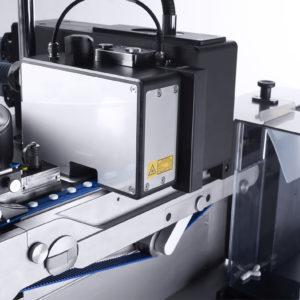

Demanding superior sorting capabilities for your packaging line

Demanding superior sorting capabilities for your packaging line

The implementation of a tablet sorting device upstream of…

The implementation of a tablet sorting device upstream of a packaging line is not just a technological upgrade but a real strategic investment in quality, efficiency, and compliance. The main advantage is the enhancement of product quality: by sorting out damaged tablets, manufacturers can ensure that only the best products reach the packaging line, therefore ensuring product safety and efficacy, and meeting the highest quality standards. Integrating a tablet sorting device can also significantly increase packaging line efficiency by minimizing bottlenecks and enhancing throughput.

Such an investment must certainly be well-considered, as imprecise sorting can lead to non-compliance with regulations, resulting in legal issues, fines, increased risk of product recall, and eventually damage to brand reputation and loss of consumer trust. To avoid such a critical situation, it is crucial to select an effective solution with superior sorting capabilities and high-precision repeatability to guarantee consistent product quality. Aim for an all-in-one solution that gets rid of all types of defective – broken, twin, and capped – tablets of any shape, even oblong. Besides, our iSort advanced solution featuring automatic adjustments based on recipes will enhance repeatability, and therefore sorting precision.

In addition to sorting capacity, Pharma Technology’s premium solution includes an automated anti-jamming system will increase sorting speed and prevent costly downtime, further optimizing your process efficiency. This efficiency can lead to higher throughput in the packaging line, allowing the manufacturer to meet production targets more easily and quickly. This will also enable the manufacturer to save not only on labor, by avoiding debugging work, but on raw materials as well, by reducing waste due to products lost or damaged during debugging.