Pharma Technology in the Top 10 “Trends Gazelles 2020”

Pharma Technology in the Top 10 “Trends Gazelles 2020”

«I am proud to say that we have the…

Advanced solutions for potent drugs

Advanced solutions for potent drugs

Introduction Highly potent active pharmaceutical ingredients (HPAPIs) represent significant…

Why Is Automated High-Speed CQA Testing Critical for Modern Pharmaceuticals?

Why Is Automated High-Speed CQA Testing Critical for Modern Pharmaceuticals?

Today’s modern pharmaceutical OSD industry puts increasingly higher demands…

Exhibition | AAPS - Orlando FL - October 22-25, 2023

Exhibition | AAPS - Orlando FL - October 22-25, 2023

We will take part in the AAPS PharmSci 360…

What is Crucial in the Success of Automatic Visual Inspection?

What is Crucial in the Success of Automatic Visual Inspection?

The Benefits of Automated Visual Inspection over Manual Inspection…

PHARMA TECHNOLOGY reveals its growth strategy 2025

PHARMA TECHNOLOGY reveals its growth strategy 2025

Pharma Technology, with more than 25 years of experience…

The Challenge

Punch sticking, hardness stability, and high ejection force are among major problems encountered with tablet manufacturing process. This causes downtime in production and sometimes tablet defects.

Extensive tests were carried out with the iSpray – the external lubrication system from Pharma Technology as well as with another “well-known” supplier to demonstrate the effectiveness of the system to solve the 4 common problems regularly encountered:

The Setup

A tablet press was equipped alternatively with the 2 types of external lubrication system:

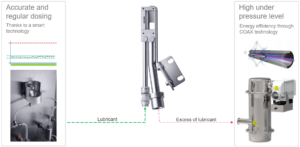

iSpray – external lubrication system with following features:

Comparative equipment – external lubrication system with following features:

The Results

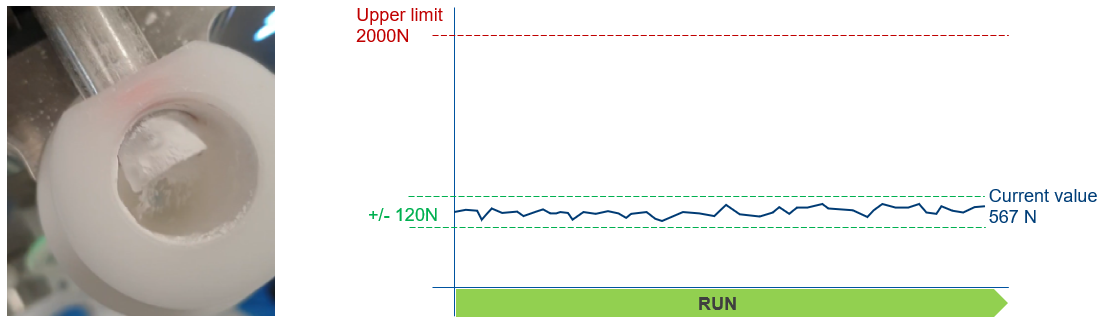

1°/Effect of the regularity of lubricant dosing on the tablet press ejection force

iSpray  🡪 Very constant ejection force 🡪 Very constant ejection force |

Compared equipment 🡪 Strong disturbance of the ejection force 🡪 Strong disturbance of the ejection force |

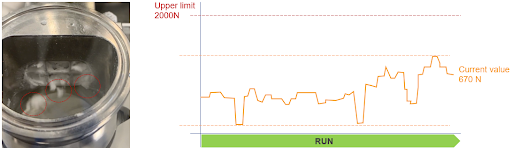

2°/ Vacuuming of the exceed lubricant / dirtiness of the press / inconsistency in content & hardness

iSpray

Constant dosing & constant hardness |

Compared equipment

Variable dosing & variability in hardness |

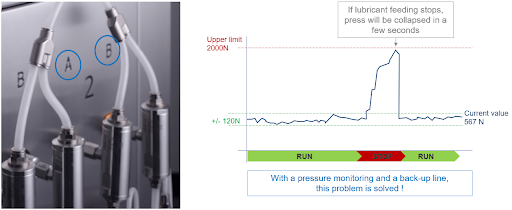

3°/Benefit of the back-up line system (Not available on compared machine)

iSpray

*Graphic shows a 3 second lubricant stop

🡪 Ensures a continuous process

In Summary

The iSpray demonstrates clear advantages over existing technology. This advanced external lubrication system allows precise application of dry lubricant to the upper – lower punch tips and die wall. The result is that a very sticky granulation can be produced continuously, without any picking or sticking, and with lower ejection force. The iSpray technology opens the door to the production of formulations that contains little or no lubricant in the blend. The dosing and vacuum system of the iSpray is far superior to the compared equipment.

Do you want to learn more about iSpray External Lubrication System ? iSpray – External tablet lubrication system | Pharmatec