CUB-20 Rapid Near Infrared Inspection of tablets & capsules

CUB-20 Rapid Near Infrared Inspection of tablets & capsules

Introduction The new CUB-20 inspection machine from Pharma Technology…

New partnership in Denmark to represent Pharma Technology

New partnership in Denmark to represent Pharma Technology

We are delighted to share our new collaboration with…

Highly efficient capsules polishing

Highly efficient capsules polishing

Introduction MediGrün is both a renowned bio-certified manufacturer of…

Roadshow | Book your stop for June in Poland

Roadshow | Book your stop for June in Poland

Our demonstration truck is ready to head out on…

100% Individual Mass Measurement of Capsules and Tablets up to OEB3

100% Individual Mass Measurement of Capsules and Tablets up to OEB3

The new CW-150 checkweigher from Pharma Technology was launched…

Exhibition | PCI Days - Warsaw, Poland - 22-23 June 2022

Exhibition | PCI Days - Warsaw, Poland - 22-23 June 2022

Come visit us during the Pharmaceutical and Cosmetic Industry…

Today’s modern pharmaceutical OSD industry puts increasingly higher demands on drug product quality control for several reasons. Amongst them are the need to produce higher quality products, to reduce waste of ever more expensive API’s and to avoid the financial cost and image deterioration related to a batch recall. Additionally, drug product manufacturers are pushed to reduce cost and lead time of their manufacturing processes, where QC (Quality Control) is a major expense and time-consuming aspect. Moreover, process scientists want more and more accurate data on multiple product CQA’s (Critical Quality Attributes) to improve the efficiency and robustness of the manufacturing process.

Conventional QC test methods and procedures are expected to become outdated in the near future due to these increasing needs of the industry, in combination with the development in recent years of innovative technologies for high-speed measurement of the physical and chemical properties of powders and solids.

Pharma Technology, being always at the forefront of technological innovation to the benefit of its customers’ process efficiency and drug product quality, has therefore developed the CU-120 fully automated high-speed non-destructive tablet inspection system. The CU-120 goes as fast as 120.000 tablets/hour and has 3 key technologies on board:

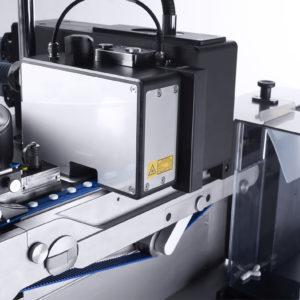

The laser scanner allows accurate tablet thickness measurement and precise determination of the tablet’s position and orientation on the inspection belt.

The 3D MRT (3-Dimensional Microwave Resonance Technology) allows for tablet mass measurement at higher throughput and accuracy than conventional multi-channel weighing systems. Combined with tablet thickness measurement and compression punch design data, the CU-120 can predict the porosity of individual tablets.

Finally, the NIR SRS (Near-Infra-Red Spatially Resolved Spectroscopy) measures the API mass fraction of multiple tablet ingredients using chemometric modelling. The SRS technology allows to cover a larger tablet surface and a deeper measurement penetration compared to single-point NIR reflection techniques, resulting in more accurate prediction of the various CQA’s.

The CU-120 is unrivalled in the combination of speed and accuracy but is also one-of-a-kind as the measurement of individual tablet mass and API fraction allows the determination of individual tablet dosage and consequently real-time measurement of Content Uniformity.

The CU-120 can be used off-line in a stand-alone machine set-up for either 100% product inspection or for partly recovery of failed batches. Alternatively, the machine can be used in-line, connected to a tablet press or integrated in a continuous manufacturing line.

The CU-120 can be delivered without the NIR SRS sensor in which case it is a high-speed measurement system for product mass and dimension (tablet thickness or capsule length). The accuracy for tablet mass measurement is ±1mg 3σ. The checkweigher CW-150 can go as fast as 150.000 tablets or capsules per hour and can be connected in line with a tablet press or capsule filler for 100% inspection of mass and dimension. The CW-150 can at any time be upgraded to a CU-120 by installing the NIR SRS sensor for API’s mass fraction at the customer site.

The CUB-X is the perfect analytical tool for smaller volumes of tablets and is specifically developed to be used either in R&D for drug product and process development, or as an on-line or at-line IPC device in commercial production. The CUB-X has a reduced throughput capacity of 20.000 tablets per hour and has no 3D MRT on board but is equipped with the same NIR SRS sensor as the CU-120. It is equipped with a 4-parameter tester for measurement of tablet weight, hardness, thickness and diameter/length at capacities up to 400 tablets per hour.

The versatility of the CUB-X allows for the system to be used in various departments and for a multitude of applications and purposes. Easy transfer of chemometric models from CUB-X to CU-120 make the CUB-X the perfect “step-in” system for later scale-up to full high-speed inspection using the CU-120.

The embedded technologies are under continuous development with the aim to add more CQA prediction capabilities, such as moisture content, non-destructive breaking force and ultimately dissolution behavior characterization.

The Quality Control product range from Pharma Technology is an extremely performant innovative technology offering an unequalled combination of high throughput and high accuracy for non-destructive CQA testing of tablets and capsules. As such, this technology offers pharmaceutical manufacturers significant economic benefits in terms of time and cost savings, as well as technological benefits in process understanding and robustness. Q-Control machines therefore play a crucial role in all stages of a drug product’s life cycle – from early product development over clinical trials and manufacturing process engineering to large-scale production including Real Time Release testing.